GPR vs. X-Ray: One Costs a Fortune, The Other Could Save Your Life.

Choosing the right concrete scanning method is more than a technical decision; it's a critical choice that impacts your budget, your timeline, and your team's safety. Our new blog post dives deep into the high-stakes comparison of GPR vs X-Ray.

Before you approve another dollar for industrial radiography, read this to discover why one of these non-destructive testing tools can lead to costly project shutdowns and mandatory site evacuations, while the other offers a fast, affordable, and safe way to prevent catastrophic utility strikes. We cut through the confusion to give you a clear cost-benefit analysis of structural imaging. You’ll gain insights into the real-world applications of GPR for rebar mapping, post-tension cable locating, and finding electrical conduits. If you are responsible for mitigating risk and protecting your bottom line, this article provides the essential facts you need to make the smart, safe, and profitable choice.

The debate over GPR vs X-Ray for concrete scanning is at the center of modern job site safety. Before a core drill or saw blade ever touches the surface, every project manager faces a critical question: what’s inside that slab? Is it simply harmless rebar, or is it a live electrical conduit, a hidden PVC pipe, or a high-tension post-tension cable? Hitting one of these subsurface hazards isn't just a mistake; it's a potentially fatal and astronomically expensive disaster, which is precisely why non-destructive testing is an essential step.

For decades, the primary choices for this type of structural imaging have been traditional industrial radiography, commonly known as X-Ray, and the more modern Ground Penetrating Radar, or GPR. While both technologies are designed to see inside concrete, their fundamental principles, operational costs, and safety implications are worlds apart. As our title suggests, one of these methods truly costs a fortune in both money and project delays, while the other is a versatile, cost-effective solution that could literally save your life. This article provides a clear comparison of GPR versus X-Ray, breaking down the pros and cons of each so you can protect your crew, your budget, and your structural integrity.

What is Industrial X-Ray? The "Costs a Fortune" Method

When you need to see inside a concrete structure, your first thought might be an X-Ray. It’s a familiar term, and in the world of non-destructive testing, it’s a method known as industrial radiography, or RT. This process works much like a medical X-Ray, but it's on a much more powerful and hazardous scale. It uses a source of potent ionizing radiation on one side of a slab and a special film or digital detector on the other. The result is a high-resolution, 2D "photographic" image of what’s inside. It’s incredibly precise at showing dense materials, like overlapping rebar and steel.

But that precision comes at a staggering price, and I'm not just talking about the invoice. This is where the "costs a fortune" part of our title comes in, and it’s a cost measured in both dollars and time.

The biggest factor is the radiation itself. Because industrial radiography uses high-intensity ionizing radiation, it is extremely dangerous to any living thing. You simply cannot have people anywhere near it while it’s in operation. This means you must establish a large exclusion zone, often evacuating entire floors above, below, and adjacent to the scanning area.

I remember being on a 20-story high-rise project in a busy downtown core. We needed to scan a small area on the 10th floor for a tenant improvement. The proposal for an X-Ray scan required us to shut down work for all trades on floors 9, 10, and 11 for an entire afternoon. That’s hundreds of workers, from electricians to plumbers to drywallers, all standing around unable to do their jobs, all on the clock. The cost of that project shutdown, that sheer downtime, was ten times more than the invoice for the scan itself.

On top of that, the process is painfully slow. You have to set up the heavy source, place the film on the opposite side, run the scan, and then, in many cases, take the film off-site to be developed. You don’t get answers right away. If the image isn't clear or the angle was wrong, you have to repeat the entire costly process. When you add up the specialized, licensed technicians, the cumbersome equipment, and the catastrophic, project-stopping downtime, you begin to see how industrial X-Ray truly does cost a fortune.

What is GPR? The "Could Save Your Life" Solution

Now, let's talk about the modern hero of this story: Ground Penetrating Radar, or GPR. If X-Ray is a stationary, hazardous "photograph," GPR is a safe, real-time "video." It’s the difference between a landline and a smartphone.

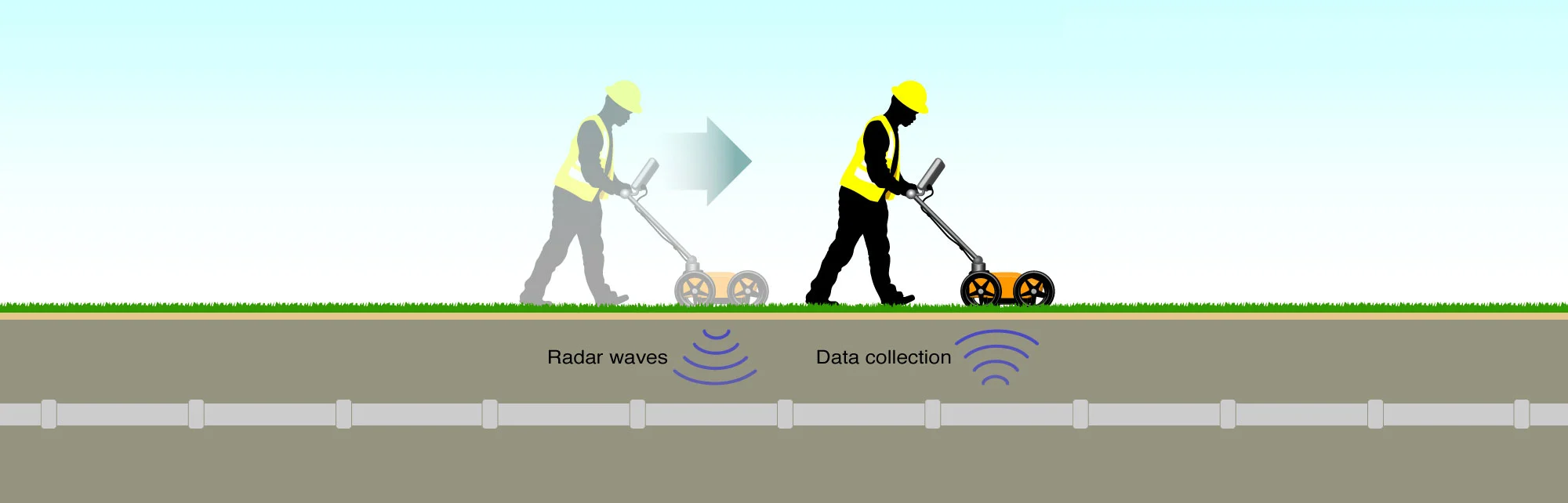

GPR works on a completely different principle. It uses safe, non-ionizing radiation, the same kind of electromagnetic waves found in Wi-Fi or your car's radio. A GPR unit sends a high-frequency radar pulse into the concrete. When that pulse hits an object or a different material, like rebar, a PVC pipe, or even a void, a portion of the signal reflects back to the antenna. The onboard computer interprets these reflections in real-time and displays them on a screen.

Think of it like a high-tech fish-finder for concrete. A skilled technician can roll the GPR unit across the slab and literally watch the subsurface map build as they go. They can see the depth, location, and approximate size of embedded targets right there, on the spot. This allows us to map out rebar, conduits, and cables and mark them directly on the surface with chalk or spray paint. The entire process is fast, efficient, and, most importantly, incredibly safe.

The "Save Your Life" Angle: How GPR Prevents Job Site Catastrophes

This brings us to the most important part of the GPR vs X-Ray discussion. The "save your life" part of the title isn't an exaggeration, it’s a daily reality for us. The true value of GPR is in hazard detection and risk mitigation. What we find, or more accurately, what we help you avoid, is what saves lives and prevents financial ruin.

I’ll never forget a new driller on one of our sites, fresh to the job and eager to get started. He was tasked with coring a 4-inch hole for a plumbing line. We had marked out the slab, but he misread the plans and set up his drill just six inches outside our "safe zone." My heart was in my throat. I ran over and hit his stop button just as he was about to pull the trigger. Our GPR scan had shown a cluster of electrical conduits exactly where he was about to drill. He was shaken, but he was safe. That's what we’re here for.

GPR prevents several types of job site catastrophes. The first and most obvious is preventing electrocution from hitting live electrical conduits. Drilling into a live, high-voltage line can cause a devastating arc-flash fire, severe electrical shock, or electrocution, not to mention blacking out a section of the building.

The second, and perhaps most terrifying, is preventing explosive cable failures. Many modern buildings use post-tension (PT) cables. These are high-strength steel tendons that are stretched, or "tensioned," inside the concrete, often with 30,000 pounds of pressure or more. They are the structural backbone of the slab. If you cut or even nick one of these PT cables, it can fail explosively. It can erupt from the concrete "like a gunshot," as many have described it, shooting out with enough force to send shrapnel and concrete flying, cause catastrophic structural failure, or kill a worker instantly. GPR is incredibly effective at locating these hidden, high-tension hazards.

Finally, GPR prevents major structural damage and personal injury by identifying rebar. While hitting a single piece of rebar isn't as explosive as hitting a PT cable, it’s far from harmless. Cutting through the primary rebar mapping compromises the structural integrity of the concrete. It can also cause powerful coring drills and saws to kick back violently, wrenching the tool from the operator's hands and causing severe lacerations, broken wrists, or worse.

The Ultimate Comparison: GPR vs. X-Ray Head-to-Head

When you put the two non-destructive testing methods side-by-side, the GPR vs X-Ray debate becomes very one-sided for most construction applications.

GPR vs. X-Ray: Safety

This is the most critical difference. GPR is completely safe. It uses non-ionizing radiation, and there is zero health risk to the operator or anyone else on the job site. We can scan in a fully occupied building, right next to other trades, with no need for an exclusion zone. X-Ray is the polar opposite. It is an inherently hazardous technology that uses ionizing radiation, a known carcinogen. It demands full site evacuation and strict, roped-off exclusion zones. In the safety comparison, GPR is the undisputed winner.

GPR vs. X-Ray: Speed & Efficiency

GPR is built for speed. A single, skilled operator can scan thousands of square feet in a single day. The data is collected, interpreted, and marked on the surface in real-time. You get your answers now. X-Ray is a slow, methodical, and disruptive process. You have to set up the source, set up the film, clear the area, run the scan, and then wait for the film to be developed. In the time it takes to get the results for a single 2-foot by 2-foot X-Ray, a GPR technician has already scanned, mapped, and cleared an entire bay. This efficiency translates directly into project savings.

GPR vs. X-Ray: Cost & ROI

When you conduct a true cost-benefit analysis, GPR is exponentially cheaper than X-Ray. The invoice for an X-Ray might already be high, but the true cost is the project downtime. Shutting down a job site for half a day can cost tens of thousands of dollars in lost labor. The cost of a GPR scan is minimal in comparison, and its Return on Investment (ROI) is massive. You're not just paying for a scan, you're paying for non-stop work, for safety, and for peace of mind. The cost of a single GPR scan is a tiny fraction of the cost of repairing one utility strike.

GPR vs. X-Ray: Versatility & Limitations

This is where GPR truly pulls away. X-Ray has a crippling limitation: it requires access to both sides of the concrete. This makes it completely useless for many common applications, such as scanning a slab-on-grade, a retaining wall, or a foundation where the other side is soil. GPR, on the other hand, is highly versatile because it only requires single-sided access.

Furthermore, GPR provides a crucial piece of information that X-Ray cannot: depth. X-Ray gives you a flat 2D image, but GPR can tell you that the rebar is 3 inches deep and the conduit is 5 inches deep. This allows for safe, shallow drilling or chipping. GPR is also superior at detecting non-metallic targets. It can easily find PVC pipes, plastic electrical conduits, and even voids or air gaps in the concrete, all of which are often invisible to X-Ray.

When Does X-Ray Still Make Sense?

To be fair, X-Ray isn't obsolete. It has one major advantage: unmatched image resolution. That "photographic" image it produces is incredibly clear. For a few niche applications, X-Ray is still the right tool. If you have a highly congested area with complex, overlapping layers of rebar and conduit, and you need to see the exact relationship between them with millimeter precision, X-Ray is a powerful option. It's also a standard for things like high-pressure pipe weld inspection.

However, for the daily needs of a construction site, like clearing an area for a core drill, a saw cut, or a trench, you don't need a millimeter-perfect photograph. You need to know where the hazards are, what they are, and how deep they are. GPR answers all three of these questions safely, quickly, and at a fraction of the cost, making it the clear choice for 99% of concrete scanning needs.

Making the Right Call: Safety, Cost, and Your Project

The debate over GPR vs X-Ray ultimately comes down to a clear understanding of true project costs. As we've explored, the high price of industrial radiography isn't just a line item on an invoice. It's a cost measured in the massive, disruptive impact of a full site evacuation, the cascading delays from project-wide downtime, and the significant liability of managing hazardous ionizing radiation on an active site. While X-Ray offers a high-resolution image, its severe limitations, like requiring two-sided access and its inability to effectively locate non-metallic conduits, make it an impractical and inefficient choice for most construction applications.

By understanding these differences, you are now equipped to make a more informed decision for your project's non-destructive testing needs. We’ve seen how Ground Penetrating Radar provides a modern, safe, and highly efficient alternative. GPR delivers real-time, actionable data, allowing for immediate structural imaging and rebar mapping right on the slab. Most importantly, it accomplishes this using safe, non-ionizing radar. This means no exclusion zones, no project shutdowns, and no hazardous exposure for your crew. You can locate post-tension cables, electrical conduits, and voids, all while other trades continue their work uninterrupted. This is what smart risk mitigation looks like.

Choosing GPR is not just a safer choice, it's a more profitable one. It’s the cheapest insurance policy you will ever buy for your project, protecting you from the catastrophic costs of a utility strike and the budget-breaking expense of downtime. Before you drill, cut, or core, don't guess what lies beneath. The expert team at JLP Tech is ready to help you visualize the subsurface and keep your project moving safely. Contact JLP Tech to get started today, and let us bring clarity and confidence to your job site.

Ready to Build with Confidence?

Don't let hidden pipes or rebar derail your project. With our expert utility locating and ground-penetrating radar services in Colorado, you can dig, drill, and build with certainty. We help you avoid costly surprises and dangerous accidents, ensuring your project stays on schedule and on budget. Whether you're a homeowner starting a backyard project or a construction manager overseeing a large build, we've got the technology and expertise to give you a clear view of what's underground.